Hip Hops

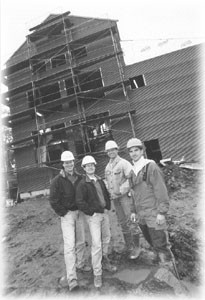

From the Ground Up: Sonoma Mountain Brewing Co. hopes to hit paydirt. From left stand CEO Tim Wallace, brewmaster Chris Atkinson, construction foreman Barry Shone, and co-owner Jerry Benziger.

Photo by Janet Orsi

Hops make a return to their

Sonoma County roots

By Steve Bjerklie

BENEATH A PATCH of dark soil near Glen Ellen, history sleeps. But when creeping underground rhizomes awaken under the soil sometime in May, they will grow faster than debt, faster than desire: they will grow up to 18 feet, in fact, in three months.

When the plants bud and are picked in September, their resin will sharpen the air with the plant’s distinctive greeny-sweet smell of resins, pineapples, and apricots. And when the essence is mulled, the flavor of Sonoma County hops will smack elegantly of the old air of Sonoma County, air that once hung heavy with hop resins and crackled with the calls and music of immigrant laborers, the taste pungent with the pine-pitch sting of hops.

For beer-making hops, part of Sonoma County’s oldest traditions–one that has been gone from the ground for 30 years after enduring for more than a century–have returned.

The return is nothing if not humble: a mere two-acre plot. Owned by the Sonoma Mountain Brewing Co., an ambitious beer-making concern established by the Benziger wine family, these two acres are so far the extent of the resurgence of Sonoma County’s once huge hop economy. And according to Tim Wallace, president and CEO of the beer company (and husband of Patsy Benziger), hop plantings in the county will probably never again attain the land use devoted to the crop in the years immediately following Prohibition, when thousands of acres were planted. “We intend to plant up to six acres,” says Wallace, “but probably no more than that. This is strictly for use at our own brewery.”

Still, the Benzigers’ commitment is more than a mere diversion: They ripped out their best merlot vineyard to plant hops because the slope, soil, and exposure were right. Commanding $1,500-$2,000 a ton, with yield featuring as much as three tons per acre, these six acres of sacrificed merlot vineyard might have contributed as much as $10,000 to $15,000 to the Benzigers’ coffers. Mike Benziger, patriarch of the family, has been quoted as calling the decision to pull the merlot in favor of hops “painful.” Elsewhere, the Healdsburg Brewing Co. has put a few experimental hop rhizomes into the ground, but nothing commercial outside of Sonoma Mountain Brewing’s plot has so far been established.

But even a new micro hop yard resurrects forgotten county history. Hops–the critical spice in beer making, giving brews the distinctive pitchy, wheaty flavor–once flourished along the Russian River. They had been grown in the county nearly as long as wine grapes, since 1858 in fact, when Amasa Bushnell and Otis Allen first harvested a crop of hop buds near Sebastopol. Sonoma County’s dense soil, mild and moist climate, and the rolling hillscapes that protect the county’s valleys from the rigors of harsh weather make an ideal hop-growing region–one of the few in the world, as it happens.

“Santa Rosa” hops, as the local type were called, were thick with flavor, perfect for dark caramel brews such as the Anchor Steam brand made in San Francisco. But a combination of factors–destructive downy mildew (which can now be controlled with modern farming), irregular bust-and-boom cycles, and a national preference after World War II for lighter lagers of the kind made by Budweiser and Miller–squeezed local hop growers until they all but gave up. The last commercial hop field in Sonoma County, on the Woolsey Road ranch owned by the Bussman family, was last harvested in the mid-1960s. Today nearly all the commercial hops used in the American beer industry are grown in Washington state.

Until Sonoma Mountain Brewing’s hops were planted last spring, all that remained of Sonoma County’s once-thriving hop agronomy were a few lonely kilns, dark and stoic as ravens against a milky sky. The remaining hop-drying kilns are almost all surrounded now by wine grapes, which turned out indeed to be the crop of the future.

TIM WALLACE is well aware of the county’s hop history. Indeed, his new brewing company sought out old-timers to find out if any members of old Sonoma County hop-picking families still lived in the area. The time of the pick, usually occurring during two hot September weeks in a rush to get the buds kiln-toasted before the plant resins dried, was unique for families and communities.

The county filled with immigrant Mexican, Italian, Japanese, and Romany families, as well as pickers from the local tribe of Pomos. Longshoreman from the docks of San Francisco came up to make the good wages paid by growers. Temporary camps for the pickers were built, streams were dammed to create swimming holes, and dances were held. Always during the harvest, the air of the entire county grew as thick and pungent as vapors from a new-baked pie with the crisp, resinous aroma of hop buds.

It was that unforgettable smell that brought both laughter and tears to the faces of stalwart members of the Dauenhauer, Imwalle, Rochioli, Ballard, and other old-time hop-picking families that Wallace and the Benzigers had invited to Glen Ellen last fall for Sonoma Mountain Brewing’s first harvest.

“We had grandparents showing their grandchildren how they picked hops,” remembers Wallace with a smile, “and here they were, doing it again for real. That’s probably a unique experience in America, the return to living people of a lost industry.”

He adds, “Hop-picking in the old days was hard work, a hard time. Hops are nettlesome plants, and a sticky substance called lupulin lies in the bottom of the hop cones. Pickers have to wear full monkey suits, with long sleeves and buttoned-up collars, which back then were made of wool. But as hard as they worked, they played hard, too. The stories we heard at our harvest were something, I tell you.”

FLORENE Dauenhauer Heck, who helped the Benzigers with that first hop harvest party, remembers that the “full monkey suits” were worn only by people who were susceptible to “hop poisoning,” a rashy skin condition not unlike the result of rubbing poison oak, “and could make picking a miserable experience.”

But not too miserable. The Sonoma Mountain Brewing hop-picking party was a cornucopia of memories. “It was just as if your first high school reunion was your 50th,” recalls Heck. “There were people who hadn’t seen each other in 50 years. The day brought back our youth, when Sonoma County was a simpler place, when everyone knew each other, when you could stand up and be counted.”

Most hop-pickers in the old days were teenagers, and half a century later those teenage memories and longings came alive again. “A friend of mine, and I’m not going to tell you her name because she’s the wife of someone prominent, asked me after she got the invitation to the Benzigers’, ‘Are they going to have any of those cute little Mexican boys there?'” chuckles Heck. “Those boys were all about 16 years old, you see, and they were like cowboys who drove hop trucks. They became all sorts of heroes that we made up in our minds.”

The teenage pickers were paid well, about $300 for a two-week or a monthlong hop season–a lot of money in the late 1940s, Heck says. “We could buy our own clothes. Why, it was enough to buy your own car!” During the short season, a typical hop farm might have as many as 60 pickers working, a critical mass of teenage excitement and innocence.

At last fall’s hop-picking party, the Benzigers provided two shuttle buses to ferry about 50 old-timers from the winery out to the hop yard. “They did a beautiful job,” comments Heck. “They had cool drinks, chairs, and they had plowed the earth. But the really amazing thing is, later I realized all of us old folks got through that whole day without any johns! That tells you how much fun we were having.”

Florene’s father, Florian Dauenhauer, is the man who single-handedly changed the hops industry with the invention of the automatic hop-picker, which he initially built and patented in 1941. His first unit was 100 feet long and two stories high, and it was to hops what the cotton gin was to cotton.

“The idea wasn’t to eliminate jobs but to pick hops faster and cleaner,” says Heck, who, with her brother now owns the Dauenhauer family company, a business that continues to manufacture automatic hop-pickers. “If you had more than 2 percent leaves and stems, the buyers wouldn’t buy your hops. The machine got it down to one to 1 1/2 percent, and our machines now are at about zero percent.”

But the automatic pickers, which were expensive, also changed the economics of hop-growing. Today, a modern hop farm with an automatic picker and its own kiln (another expensive asset) has about $2 million invested in harvesting equipment alone. Smaller farmers couldn’t afford the investment and were gradually swallowed up by larger farms. Some of the Washington state farms grow hops on thousands of acres.

The Benzigers, with so few acres devoted to hops, were not about to invest $2 million in harvest technology. Florene happened to know a hop farmer in England who had developed a portable kiln, and he passed on the plans for his invention to Sonoma Mountain Brewing.

FROM A BUSINESS perspective, there’s no great story or romance as to why a successful wine-making family suddenly became enamored of beer. The boom in microbrewing got the Benzigers and Wallace interested in hops, not history or its preservation. In fact, while attending Harvard Business School in 1987, Wallace was commissioned by the Benzigers to study the microbrew market with an eye toward making an investment.

“What the study showed was a very attractive, very small-niche beer business,” he says. “The business had a lot of dynamics similar to what was going on in the wine business. The distributors and retailers were all the same. And the microbrews were being purchased by discriminating buyers, the same kind of people who like to buy fine wine.”

At the time, the U.S. microbrew industry comprised 21 breweries, including such historic outfits as Anchor Steam. Today there are more than 300 small, niche-type beer-making enterprises, nine of which operate in Sonoma County. And now 10 years after he wrote it, Wallace is putting his business study into action.

Sonoma Mountain Brewing Co., still under construction, will feature an extensive taproom, with at least four brews on tap at all times, although only two–a golden pilsener and an amber lager–will be distributed by the company for retail sale. Wallace says he hopes to have the taproom open in late spring, possibly by Memorial Day. The company’s brewery is also under construction. Not content to copy the big American makers of pale, tasteless beer, Sonoma Mountain Brewing bought an entire brewery in Germany–“because the best beer comes from Germany,” says Wallace–and had it shipped, piece by copper piece, to its Glen Ellen site, along with a German engineer to translate the blueprints and oversee installation of the complicated equipment.

To date, the Benzigers have invested $3 million in the venture. Total production at Sonoma Mountain Brewing will top out at 100,000 cases annually.

“We’re America’s first estate microbrewery,” Wallace boasts, not without good reason. “We’re growing our own hops, the water for our brews is from our own well, and we’re propagating our own yeast. We buy only barley from the outside.” He is in fact trademarking the term “estate” for use on a beer label–the first time in America the word has been used to describe a facility for brewing beer. But Wallace is quick to point out that the Benziger beer enterprise, unlike the wine business the family sold a few years ago for $80 million to the spirits multinational Heublein Inc., will remain small.

“We want to be Sonoma County’s local brewery,” he states. Stressing the point, Wallace says Sonoma Mountain brews initially will not be distributed for sale outside of a 50-mile radius from Glen Ellen, and will be available throughout California perhaps only by the end of the decade. Do not expect to see Sonoma Mountain Brewing ads on television during a Super Bowl or World Series. Indeed, Wallace says the only ballgames where you’ll be able even to buy the beer are at the Crushers’ games in Rohnert Park.

“We want to do it right. We want to take the time and the care to make a truly great beer. We’re experimenting right now with nine different hop varieties, which all gave us uniform growth the first year. We want to find the right two or three to blend for the formula that will work best for us,” says Wallace. Formulas are the secret of great beer-brewing, and Sonoma Mountain wants to get its formula right from the ground up. Wallace approaches his job with the practical unfussiness of, well, a graduate of Harvard Business School–albeit one with soul.

After word about the success of the first harvest got around the county, history had a little surprise in store for Tim Wallace, the man who found Sonoma County’s old hop families and invited them back into their own past. “I began to get calls from grape growers. They all wanted to know: How do you grow hops? How much land do I need?’

“Sonoma County had 3,000 acres of hop yards all the way up into the ’50s,” he says, shaking his head. “Maybe some of those acres will come back again. I sure hope so. If they did, that’d be something. That’d really be something.”

From the January 30-February 5, 1997 issue of the Sonoma County Independent

This page was designed and created by the Boulevards team.

© 1997 Metrosa, Inc.