It’s midnight on the bottom floor of UCSC’s physical science building. The doors are locked and the motion-sensor lights have been dim for hours, but doctoral student Hanyu Wang is still in the lab, compelled by a scientific pursuit so gripping, sleep seems trivial.

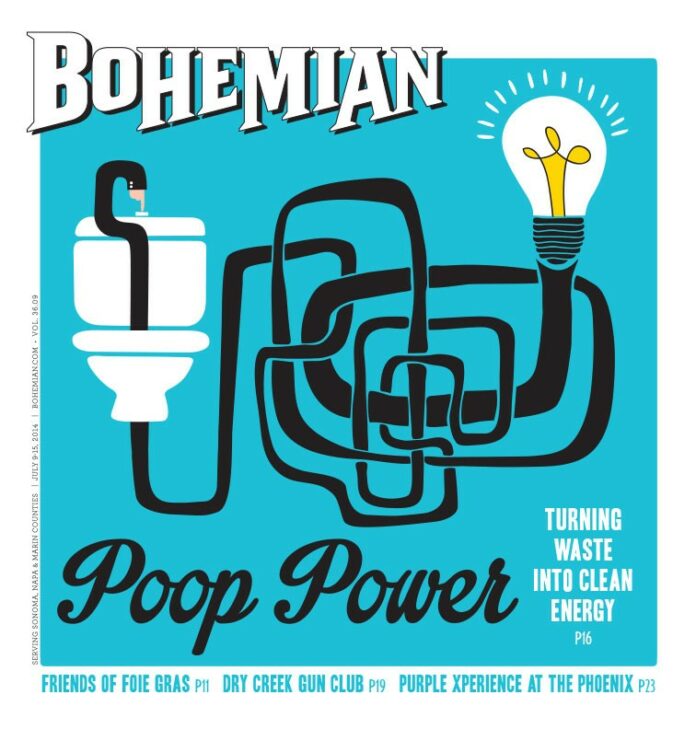

After five years, Wang and Yat Li, chemistry professor at UCSC, have successfully engineered a device that converts, literally, what we flush down the toilet into a zero-emission hydrogen fuel that could power a rocket ship. But here’s the best part: the hydrogen-based fuel comes from purely natural resources—sunlight and wastewater. In other words, it’s entirely sustainable.

Sustainable, and pretty disgusting—at least, as far as the raw materials go. They’ve made this an unusual and downright odiferous project for Wang, but she does her best to take the funk in stride. Because even though the sewer water smells awful, it contains the cornerstone of the entire operation: a special type of electricity-generating bacteria.

“I like my project a lot,” says Wang. “I really feel like I’m interacting and connecting with the bacteria. I just really enjoy the process.”

Her lab mates, however, don’t share the same connection with the electrogenic bacteria that Wang has forged over the years, and support their fellow researcher from a respectable distance.

“The wastewater always smelled weird when I was working with it,” Wang recalls.

“You’ve smelled the sewer before, right? It was just like that. People didn’t like to go around my bench, because it was just too smelly.”

But it’s all in the name of science. One day, Wang’s research may hugely impact the way we think about energy production.

There is poop-to-power innovation happening in the North Bay too. The Sonoma County Water Agency has a couple of rank assets in the renewable-fuels portfolio. In 2011, the agency contracted to build a “farm to fuel” chicken-excrement biogas converter at its wastewater plant. There’s also a Petaluma biogas filtration plant at the county-run landfill. Those systems feed the PG&E grid and create fuel for county vehicles.

In western Marin County, the Straus and Giacomini dairies use methane digesters to convert cow manure to power, enough to run the dairies and put some back on the grid. Best of all, brags the Straus website, the digester takes the stink off the barn as it generates power for owner Albert Straus’ electric car.

But hydrogen packs a bigger wallop as a fuel source. With a potential to power cars and industrial machines without harmful emission, hydrogen is an extremely appealing alternative fuel. Though it’s often touted as a fuel of the future, it’s actually been recognized as a viable energy option for more than 50 years—and NASA has safely used it as a power source for missions since its inception in 1958. With its promise of drastically cut carbon emissions, labs across the country have been working for years to make hydrogen fuel accessible to the masses. So what’s the hold up?

Cost, for one thing—the production of hydrogen fuel has been prohibitively expensive, so far. Which is precisely why the research at Li’s lab stands out: the project runs on sunlight and sewage—two energy sources that are not only cheap but virtually unlimited. Once the device is built, the raw materials cost next to nothing.

“We use what’s naturally available to us—the wastewater and sunlight,” says Wang. “We’re in golden California, so we take advantage of that.”

[page]

The project started in 2009, when Li’s wife, Fang Qian, staff scientist at Lawrence Livermore National Laboratory, saw potential for a groundbreaking collaboration. Li and Qian both specialize in devices that create hydrogen gas—Li’s using the sun, and Qian’s using bacteria.

Led by Li, the UCSC research team has coupled the two devices—a photoelectrochemical cell (PEC) and a microbial fuel cell (MFC)—to make one self-sustaining, water-treating, hydrogen-fuel-producing mega-device. We’ll call the hybrid device the PEC-MFC.

The PEC captures sunlight, and uses its energy to kick-start a process known as electrolysis. During electrolysis, water is split into hydrogen and oxygen, and then released as gas. The MFC not only creates hydrogen gas, but also uses electrogenic bacteria to produce electrical energy. While splitting water to make hydrogen seems reasonable, Li recognized that California is in a drought and water regulation is tight, so they tweaked their initial approach.

“The idea is to replace the MFC ‘solution’ [pure water and cultured bacteria] with wastewater that contains these kinds of bacteria naturally,” says Li.

To ensure authenticity, researchers swapped the pure water solution with wastewater directly from the water treatment facility in Livermore, Calif. If you know someone who lives in Livermore, thank them—they may have unknowingly contributed to this research.

Though it may be counterintuitive, Livermore’s dirty water is what makes the clean energy process sustainable. Human wastewater naturally contains organic material and electricity-generating bacteria.

Separately, the PEC and MFC both require an additional energy boost to drive full-fledged hydrogen production, and the added voltage is pricey. But putting them together creates a symbiotic solution: the bacteria in the MFC feed off of the organic matter in the wastewater, and during digestion, produce energy in the form of electrons. These electrons are channeled to the PEC, supplying the final electrical nudge needed to create the hydrogen fuell source. In that sense, the MFC acts as a battery, providing energy and enabling the PEC to continuously make hydrogen gas. Essentially, as long as wastewater is available to the bacteria in the MFC, the PEC bubbles out hydrogen at a fairly constant rate.

On the flip side, as the PEC splits water, the hydrogen is stored in a cylinder and doled out as useful energy for the MFC. Between the chemical fuel-kick from the PEC and the bacteria-generated electrical jolt from the MFC, the hybridized device can take care of itself. It’s a self-perpetuating cycle that works to balance and propagate its counterpart.

But that’s not to say Li and his team didn’t experience their share of unique issues. Occasionally, and for no apparent reason, the PEC-MFC simply stopped working. Wang suspects that the different bacteria in each batch of wastewater may have caused the PEC-MFC to briefly misbehave—some pools may have more electrogenic bacteria than other, especially because the wastewater is allocated for a small-scale setup.

“Each batch of wastewater is different. Maybe the bacteria aren’t happy that day, or are feeling lazy. They are live cells—they have their temper too,” Wang jokes. “There wasn’t a clear reason why some batches were better than others. So I’d try again, and it’d work.”

With the overall striking success of the PEC-MFC in the lab, Wang and Li have big plans for future projects. Literally. The ultimate goal is to create a large-scale PEC-MFC that harnesses the same stinky raw materials and functions in the same self-perpetuating cycle—the only difference being the sheer quantity of hydrogen gas produced.

A PEC-MFC that’s large enough to convert and pump hydrogen directly from a wastewater treatment facility is still just a schematic, but Li and Wang are actively taking steps toward achieving such a mega-device.